Conveyor Machine

Friction Conveyor System (FCS)

A "friction conveyor system" that uses a friction drive system that does not use chains, which NKC is proud of. This epoch-making system, which can be called a drive revolution, is currently receiving a great deal of attention from all over the world as the next generation of the inverted conveyor system (conveyor engineering) that was born in 1985. By converting the driving force of the motor into frictional force and transporting the dolly, the transport speed is increased, and further, noise reduction, improvement of work environment, reduction of equipment and running cost, etc. are produced. An advanced system that brings together the know-how and technological capabilities that NKC has accumulated through the transport aircraft business will bring evolution to all industries.

Characteristic of FCS

- Maximum speed: more than 360m/min

- Speed range: 1:50

- Acceleration: 1.08G

- Light weight and modular design allow for simple and compact system layouts.

- Modular construction with no need for auxiliary drive chain provides conveyor engineering maximum flexibility and future modifications.

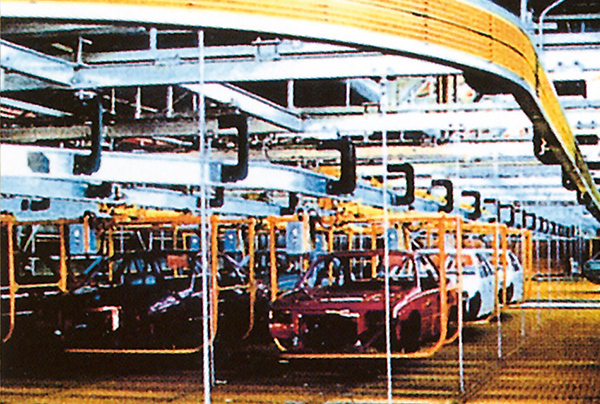

Train System

Building an efficient production system linked to a series of processes such as development, design, sales, and distribution is currently an indispensable element as companies promote CIM. In order to meet the needs of these times, NKC has continued to develop more accurate production systems by utilizing the advanced technology and know-how cultivated over many years in chain conveyors. The system that can be said to be the crystallization of the results is the motor train. With this precision, which is indispensable for CIM construction, such as ± 0.1 mm positioning stop accuracy, high speed, variable transfer, and accurate speed as instructed, it will lead the sophistication of speedy and efficient production systems.

Characteristic of Overhead Train System

- Maximum speed: more than 360m/min

- Speed range: 1:50

- Acceleration velocity: 1.08G

- System layout is simple and compact requiring few auxilary facilities.

- Reliable and proven equipment that is flexible enough to meet almost any production requirement.

Characteristic of Floor Train System

- Maximum speed: more than 360m/min

- Speed range: 1:50

- Acceleration velocity: 1.08G

- Simple, uncluttered design allows for maximum accessibility to the product.

- System flexibility is magnified with the use of track switches, turn tables and lift sections.

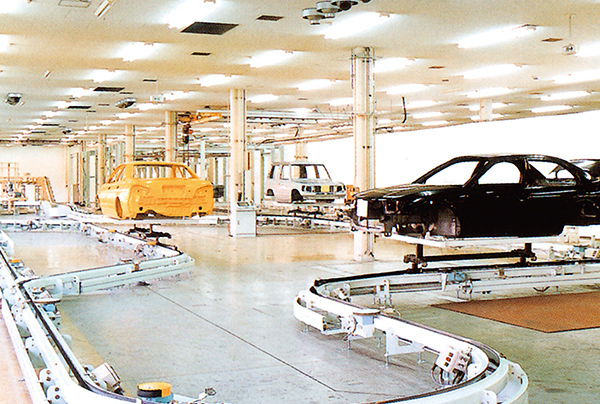

Chain Drive Type

The inverted conveyor system (conveyor engineering), which is highly workable and trusted by domestic and overseas manufacturers, is used in many manufacturing plants due to its versatility. The ability to handle a wide variety of processes such as welding, exterior, interior, engine assembly and mounting, and baking finish is so flexible that most lines in the factory can be configured with inverted. In addition, the structure that facilitates the work approach from four directions by supporting it from below greatly enhances work efficiency.

Characteristic of Chain Drive Type

- Outstanding efficiency and longevity.

- Diverse applications options.

- Excellent cost to performance ratio.

- Simple and high-quality components.

- Easy Maintenance.

- Shortened design time due to modular construction.

- Accumulation and non-linear production capabilities.

- Smooth transition from line to line with a dog-to-dog transfer.

Past Projects

ASSB #1 (TOYOTA)

Year: 1997

Body Shop: -

Paint Shop: 50%

Ass'y Shop: 100%

Remarks:

- Paint Shop - PT&ED Line, Oven Line

- Assembly - 3 Main Line. Each Line Includes Trim Line, Chassis Line and Final Line. (OHC, Slat CV, Traverser Hangers, Table Lifters & EMS).

ASSB #2 (TOYOTA)

Year: 2017

Body Shop: -

Paint Shop: -

Ass'y Shop: 100%

Remarks:

- Assembly – Coloured line, Trim Line, Chassis Line, Final Line and Inspection Line.

PMSB (Perodua)

Year: 1993

Body Shop: 100%

Paint Shop: 100%

Ass'y Shop: 100%

Remarks:

- Body Shop – Shell Line,

- Paint Shop – PT& ED Line, Oven Line & Booth Line.

- Assembly – 3 Main Line. Each Line Includes Trim Line, Chassis Line and Final Line. (OHC, CPC CV, Slat CV, FCS, EMS, Side Lifters & Drop Lifters).

- Including WBS Line, PBS Line Bumper Line & Engine Line.

PMSB Extension (Perodua)

Year: 2002

Body Shop: 100%

Paint Shop: 100%

Ass'y Shop: 100%

Remarks:

- Body Shop – Shell Line.

- Paint Shop – PT& ED Line, Oven Line & Booth Line.

- Assembly – Trim Line, Chassis Line & Final Line.

PMSB (Perodua)

Year: 2006

Body Shop: 100%

Paint Shop: -

Ass'y Shop: -

Remarks:

- WBS (Welded Body storage)

- Shell Line

PMSB (Perodua)

Year: 2017

Body Shop: 100%

Paint Shop: 100%

Ass'y Shop: 100%

Remarks:

- New Model Expansion

PGMSB (Perodua Global)

Year: 2014

Body Shop: -

Paint Shop: -

Ass'y Shop: 100%

Remarks:

- Assembly - Trim Line, Chassis Line and Final Line.

- Including PBS Line & Door Line (OHC CV, FCS CV, Slat CV).

HMSB #1 (Honda)

Year: 2002

Body Shop: -

Paint Shop: 50%

Ass'y Shop: 100%

Remarks:

- Paint Shop - PT & ED line.

- Assembly – Trim Line, Chassis Line and Final Line. (EMS, CPC CV & Slat CV).

HMSB #2 (Honda)

Year: 2013

Body Shop: 100%

Paint Shop: 100%

Ass'y Shop: -

Remarks:

- Body Shop – Main Body Line.

- Paint Shop – PT&ED Line, Oven Line & Booth Line.

- Including PBS Line. (OHC CV, FCS & Drop Lifters).

Tan Chong Nissan (KL)

Year: 1976

Body Shop: -

Paint Shop: 100%

Ass'y Shop: 100%

Remarks:

- Assembly & Paint shop (Floor CV)

Honda Motorcycle Boon Siew

Year: 2012

Body Shop: -

Paint Shop: -

Ass'y Shop: 100%

Remarks:

- AF MAIN LINE & JOINT LINE (FCS & SLAT CV)

Honda Motorcycle Boon Siew

Year: 2020

Body Shop: -

Paint Shop: -

Ass'y Shop: 100%

Remarks:

- AF New Scooter Line

Contact us

DROP US A MESSAGE